Manufacture Process

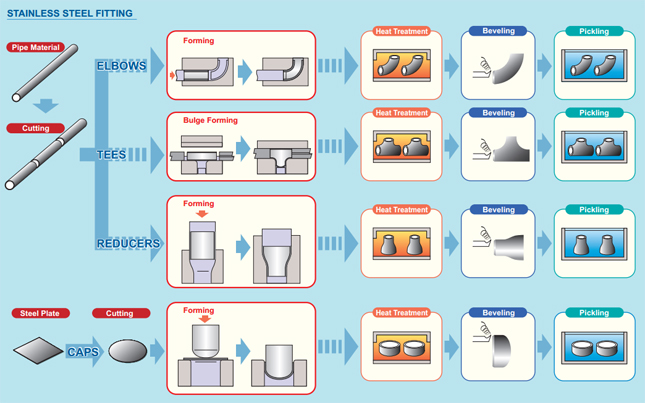

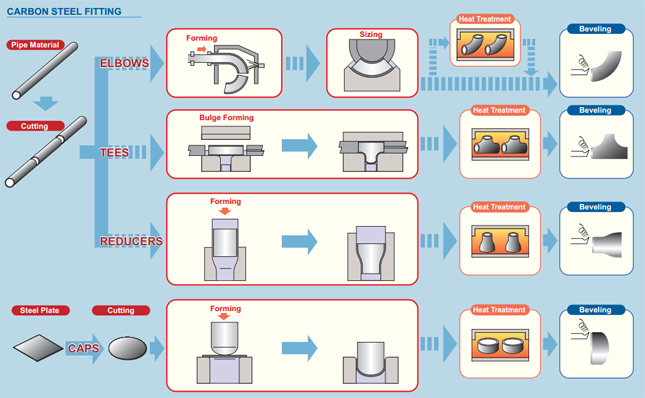

Buttweld Fittings manufacturing Process

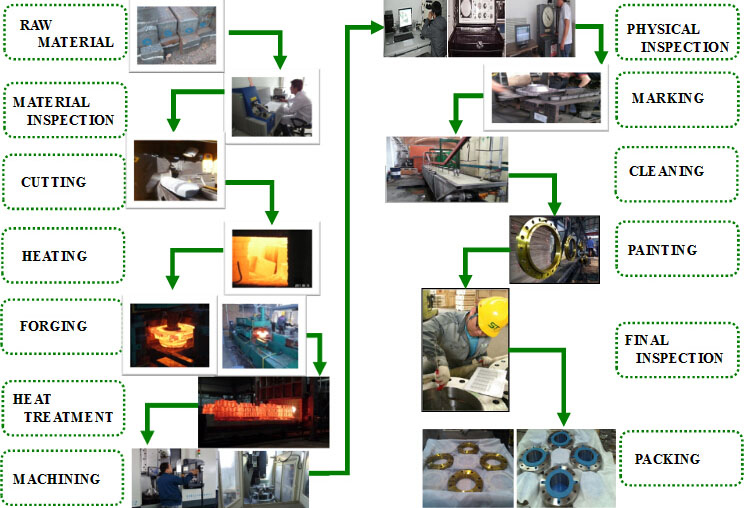

Flanges Manufacturing Process

Manufacturing Procedure for Butt‐Weld Pipe Fittings:

Material Selection: The process starts with the selection of appropriate materials based on the

specifications required for the final product. Common materials for BW pipe fittings include carbon

steel, stainless steel, alloy steel, and various other metals.

Cutting and Shaping: Raw materials, typically pipes or steel plates, are cut into appropriate sizes and

shapes using cutting machines such as saws or plasma cutters. Forging or casting may also be

employed to form the basic shapes required for the fittings.

Forging / Forming: The shaping process involves forming the raw materials into the desired shapes

for the fittings. This can be done through various methods such as hot forming, cold forming, or

machining, depending on the material and the complexity of the fitting.

Heat Treatment (if necessary): Depending on the material used and the desired properties of the

final product, heat treatment processes such as annealing, normalizing, or quenching and tempering

may be employed to achieve the required mechanical properties and microstructure.

Machining: Machining processes such as turning, milling, drilling, and threading are performed to

achieve the final dimensions and specifications of the fittings. This step ensures that the fittings

meet the required tolerances and surface finish.

Welding: Butt welding is the primary method used to join pipe fittings. In this process, the ends of

the pipes or fittings are beveled to create a V‐shaped groove, and then they are joined together by

welding along the seam. This creates a strong and leak‐proof joint.

Quality Control: Throughout the manufacturing process, various quality control measures are

implemented to ensure that the fittings meet the required standards and specifications. This

includes dimensional inspection, visual inspection, non‐destructive testing (such as ultrasonic testing

or radiographic testing), and pressure testing.

Surface Treatment (if necessary): Depending on the requirements, surface treatment processes

such as pickling, passivation, or coating may be applied to protect the fittings from corrosion or to

improve their appearance.

Final Inspection and Packaging: Once the fittings have been manufactured and tested, they undergo

a final inspection to ensure that they meet all the specified requirements. After inspection, the

fittings are properly packaged and prepared for shipment to the customer.

Manufacturing Procedure for Forged Pipe Fittings:

Material Selection: Choose the appropriate materials based on the specifications required for the

final product. Common materials for forged pipe fittings include carbon steel, stainless steel, alloy

steel, and other metals.

Heating: Heat the selected raw material to a suitable forging temperature. This temperature varies

depending on the material and its properties. Heating can be done in furnaces or using induction

heating methods.

Forging: Shape the heated material into the desired fittings using forging equipment such as

hammers or presses. The forging process involves applying controlled pressure to the heated

material to deform it into the required shapes. This can be done through open die forging or closed

die forging methods.

Trimming: After forging, excess material or flash is removed from the forged fittings using trimming

or cutting processes. This step ensures that the fittings have the correct dimensions and surface

finish.

Heat Treatment: Depending on the material and the desired properties of the final product, heat

treatment processes such as annealing, normalizing, or quenching and tempering may be applied to

enhance the mechanical properties and microstructure of the fittings.

Machining (if necessary): Some forged fittings may require additional machining operations to

achieve the final dimensions and surface finish. This can include processes such as drilling, milling,

threading, or grinding.

Surface Treatment: Apply surface treatments such as pickling, passivation, or coating to protect the

fittings from corrosion or to improve their appearance.

Quality Control: Throughout the manufacturing process, various quality control measures are

implemented to ensure that the fittings meet the required standards and specifications. This

includes dimensional inspection, visual inspection, and non‐destructive testing (such as ultrasonic

testing or dye penetrant testing).

Final Inspection and Packaging: Conduct a final inspection to ensure that the fittings meet all

specified requirements. After inspection, the fittings are properly packaged and prepared for

shipment to the customer.

Manufacturing Procedure for Flanges:

Material Selection: Choose the appropriate materials based on the specifications required for the

final product. Common materials for flanges include carbon steel, stainless steel, alloy steel, and

other metals.

Cutting and Shaping: Cut the raw materials into the desired shapes and sizes using cutting machines

such as saws, plasma cutters, or water jets. The raw materials may be in the form of plates or

forgings.

Forging / Forming: Shape the cut materials into the specific flange configurations using forging,

rolling, or machining processes. Forged flanges are produced by applying controlled pressure to

deform the heated material into the required shapes. Rolled flanges are formed by passing the

heated material between rollers to gradually shape it. Machined flanges are produced by removing

material from a solid block or forging to achieve the desired dimensions and contours.

Drilling and Tapping: Drill holes and tap threads into the flange faces to accommodate bolts for

connecting to piping or equipment. This step ensures that the flange can be securely attached to

other components in the piping system.

Heat Treatment (if necessary): Depending on the material and the desired properties of the final

product, heat treatment processes such as annealing, normalizing, or quenching and tempering may

be applied to enhance the mechanical properties and microstructure of the flanges.

Surface Treatment: Apply surface treatments such as pickling, passivation, or coating to protect the

flanges from corrosion or to improve their appearance.

Quality Control: Throughout the manufacturing process, various quality control measures are

implemented to ensure that the flanges meet the required standards and specifications. This

includes dimensional inspection, visual inspection, and non‐destructive testing (such as ultrasonic

testing or dye penetrant testing).

Final Inspection and Packaging: Conduct a final inspection to ensure that the flanges meet all

specified requirements. After inspection, the flanges are properly packaged and prepared for

shipment to the customer.